Thermal oxidisers – Basic Introduction

Thermal oxidisers, or thermal incinerators (TO), are high-powered industrial machines used to improve air quality by modifying waste gas and emissions into stable compounds. Solvent emissions of harmful substances are released into the air during multiple industrial activities. They consist of ammonium, sulphur oxides, nitrogen oxides, dust, mercury and other heavy metals. You may know them under the VOC (volatile organic compounds) and HAP (hazardous air pollutants).

VOCs are usually human-made compounds with low water solubility and high vapour pressure. HAPs are toxic air pollutants. Dangerous emissions negatively affect the environment and human health, showing in severe health conditions such as bronchitis, asthma and even cancer. The thermal incinerator has a massive role in the thermal deterioration of the gas emissions mixed with the air. Through the procedure, the emissions are transformed into pure combustion products, water and CO2.

Any thermal oxidizer system manufacturer will tell you that the appliances mostly rely on the oxidation brought by combustion. There are three main types of TO: regenerative, direct-fired and recuperative. They vary in their methods of heat utilisation and heat recovery. Choosing a suitable thermal incinerator for a manufacturing plant can be challenging. With technological advances and structure developments processing VOCs and HAPs have radically improved. And the cost? Thermal oxidizer system cost varies by type, size, properties and location of the installation.

Thermal oxidizer system – How is it made, and how does it work?

Thermal oxidisers are paramount in any manufacturing plant that produces HAPs, VOCs, odours or other harmful emissions. Industrial facilities must follow rigorous rules and procedures regulating emissions content. To stay compliant with the laws, they must eliminate pollutants from the exhaust and prevent emissions from harming the environment.

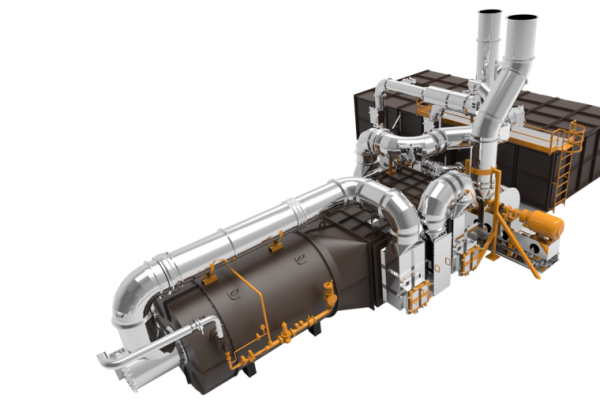

The most energy-efficient and cost-effective equipment to do the job is a thermal oxidizer system Manufacturers improved their features, capabilities and applicability, which allows them to improve, air quality by 99,9%. Thermal oxidisers consist of a system for waste feed, inlets for air (air dampers or blowers) and a pilot (waste burner and assist fuel burner).

They also have fuel piping trains (to the burner and pilot) and high-temperature refractory liners in the combustion chamber. Temperature, fuel, air and over-fire controls are all included in the flame safety package. The structure is completed with sample ports for measuring the pollution-control device’s performance. A thermal oxidizer system acts like a reactor when the stream of preheated waste gas is oxidised at high temperatures. Polluted air is pushed through the machine with the help of a system fan. For the combustion, the process airstream has to be sufficiently oxygenated. If that does not happen, ambient air is introduced.

The air is preheated before entering the chamber by passing through an air-to-air heat exchanger. To ensure the decomposition of emissions, the air is heated to a high temperature and maintained at that temperature with turbulence. The VOCs are converted to water and CO2. Then the clean, hot air passes through the heat exchanger’s hot pass while clean, cooled air is released into the atmosphere.

Thermal oxidisers and the main advantages of their use

A thermal oxidizer system guarantees that the facility has a positive impact. Through the years, they have become one of the most effective methods to treat hazardous emissions and air pollutants. Their use offers many advantages, the main being able to obey the regulations and laws while keeping operating costs low. High thermal efficiency and low operating cost are vital for manufacturing plants.

Their rugged yet simple and practical exterior has easy access to all major components for repair or upkeep. Advanced thermal technology makes them more energy efficient and prolongs their lifespan. Thermal oxidisers tend to have low operating costs due to high heat recovery and innovative design. Each thermal incinerator offers distinct advantages which suit various parameters, efficiency preferences and destruction requirements.

What to consider when buying a thermal oxidizer system, and what is the cost?

Thermal oxidizer system cost is something you should consider when investing. Each system has a distinctive design offering trustworthy and efficient contaminant capture. Incinerator selection usually depends on numerous factors. Energy, treatment, pollutant destruction efficiency and facility conditions. However, the most important ones are the three T’s. Temperature, turbulence and time.

These co-dependent and crucial factors determine the performance. In addition to the three T’s, reliability, ongoing operating costs and equipment life have a principal role in choosing the perfect TO. When selecting the Thermal oxidizer system, make sure it serves a purpose and solves the right problem. A reliable structure will prevent machine downtime, which can lead to financial loss. The cost of thermal incinerators varies by type, technology, dimensions and modification. Obtaining a high-efficient appliance will not only reduce the cost of production but also considerably change the paste of the facility.