Which sectors should use industrial dryers?

The need for industrial dryers is not limited to a specific sector or branch of economy. While some sectors are dependent upon the processes, there are many other fields where industrial dryers can fasten the production and bring about welcome savings. Several industry branches use exposure to air for a variety of purposes. To name but a few: the paint industry, glass and plastics production, any stationery, such as ink and adhesive production, while food processing and automotive industries are very large areas where ventilation is needed. In order to cater for those needs effectively and economically, producers are investing into industrial dryers. Their benefits are:

- Time saving.

With the temporal dimension being of utmost importance for the delivery on time, many manufacturers appreciate any possibility to quicken up the production process. Investing into a device to save valuable time can lead to additional savings on money and energy. - Energy saving.

As stated above, time savings are crucial for many sectors that have been able to quicken up their production by investing into industrial dryers. By making this choice, manufacturers have also been able to reduce the cost of the energy needed for a product’s delivery. Energy-efficient devices are crucial for meeting the ecological and CE production standards. - Money saving.

In conclusion, the added benefit of saving time and saving on the cost of energy is an aggregated cost of saving money. This amount can be invested into further improvements to the production process, thus leading to a raised standard of quality for products.

The cycle of dehydrating is usually separated into four stages: the loading is followed by the actual desiccating. After that, cooling should be dine, followed by the unloading of the material. There are devices where these stages can be exercised in parallel, while in other types of devices they are handled consecutively.

A continuous dryer can be used for large quantities of material

A continuous dryer is among the types of devices most commonly used in the food industry. Often employed for desiccating fruit, the continuous dryer increases the edibility of the food. This is guaranteed through the dehydrating process, which takes place continuously in the device. Any spread and growth of bacteria, yeast or mould is inhibited. The aeration process in a continuous dryer is ongoing, hence the name.

This is associated with comparatively large quantities of food that can be prepared in such a way. If one company alone can not fill-up the capacities of the device, partnerships or consortiums can be built to allow for a maximum effectiveness and use of the machine. The life span of the food is thus prolonged and together with proper storage, products with such preparation can be kept for several years.

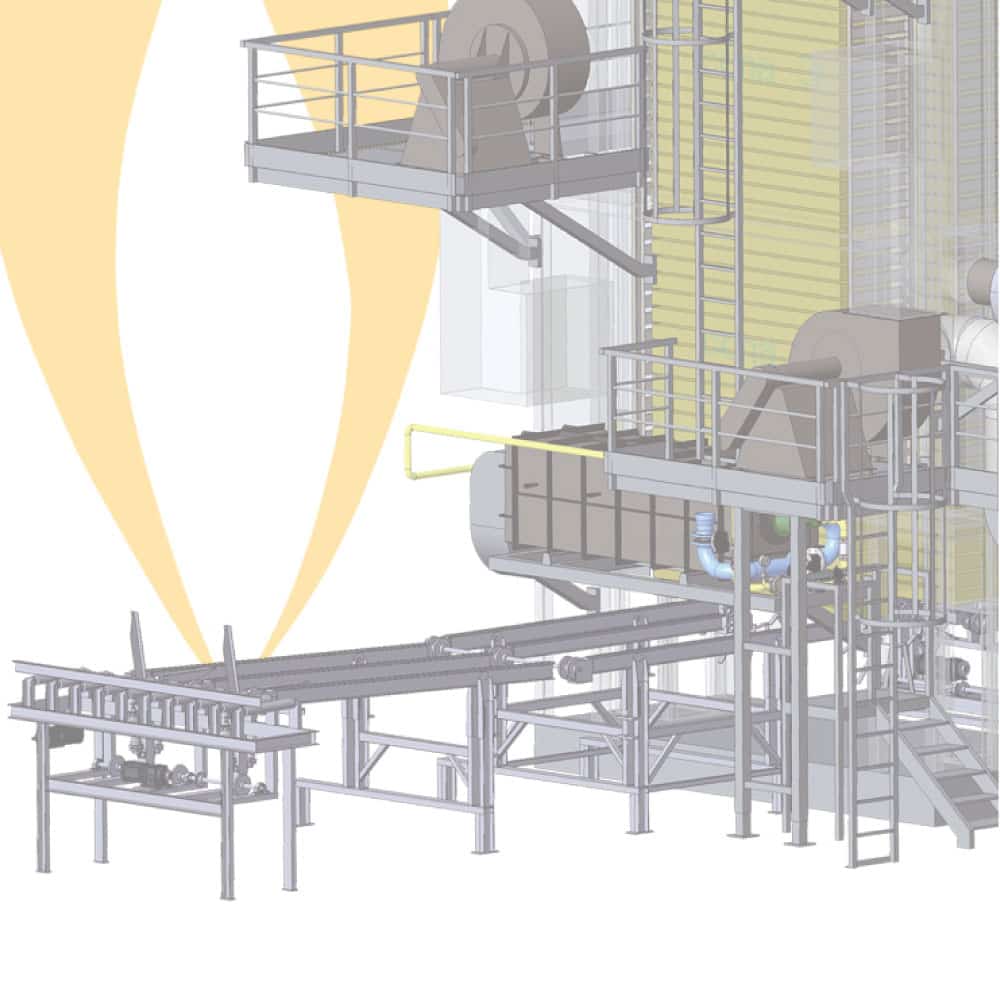

This type of device is often associated with a tower structure, where the level of production is high and elevators, as well as storage silos occur.

Use a chamber dryer if you are in the food-processing sector

A chamber dryer, too, is not unknown to the manufacturers in the food-processing sector. It is commonly known for dehydrating the products that can be desiccated in phases, like grains. This process is indispensable for proper storage of several types of products, legumes and cereals among them. The technological advancements of chamber devices have led to many bug industrial farms and complexes to rely heavily on the use of these devices. What are the key advantages of this type?

- Predictability

For producers of large and medium level, it is of key importance to be able to predict their production quantities regardless of external factors. The use of a device that allows for a steady flow of ventilation is a big advantage for planning and scaling. - Constant and varied production

There are already enough unpredictable factors in the agricultural branch. The fact that this device is constantly being used with a steady output for various kinds of products, is an aspect of predictability that greatly reduces the risks for the producer. - Regular maintenance

When installed by a professional, the devices are easily maintained and regularly supervised. This facilitates any issues arising on the ground and eases the burden on the crop producer.

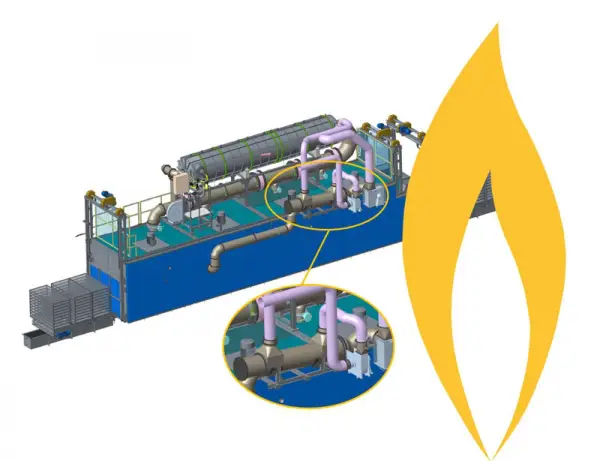

An advantage of the rotary dryer is the possibility of recovering the heat

Finally, a rotary dryer is perhaps the most generally well- known type of this device. What is more, this type has a big advantage, which is the possibility of recuperating the heat. It allows for direct and indirect heating, which can greatly reduce the energy costs. Energy savings, consistency in the operation, as well as relatively high capacity are among the other advantages of this type of machine.

To determine the type that is right for you, together with answering your technical and production demands, please contact our team of experts.